Ventilation , open fires and Cavity wall insulation

Our living room has what's called an open flue solid fire - or an open fire for burning coal and wood to you and me.

For a fire to function safely it needs to be able to draw new air into a room , use the oxygen as part of combustion and allow the heat and smoke is drawn up the chimney and out of the building.

Old buildings were pretty draughty and the the fire could draw enough air though the house but as we have strived to make houses airtight, building regulations have dictated that open fires require a dedicated vent which travels through the cavity wall to the outside world in order for the flue to work effectively.

As part of the CWI installation checks, any room with an open fire was required to have an airvent

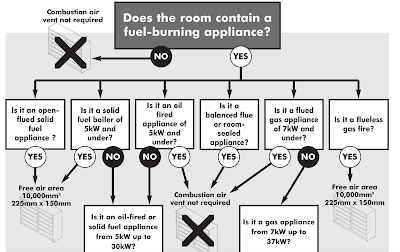

From CIGA Technical install guide "'Flues, chimneys and combustion air ventilators 2006" which is the guidance in use when our CWI would have been installed.

It states quite clearly that a 225mm x 125mm sleeved air-vent is required before installation can proceed:

It states quite clearly that a 225mm x 125mm sleeved air-vent is required before installation can proceed:

The combustion air supply must be isolated from the cavity, to guarantee an adequate supply of combustion air to the appliance(s). It is essential that the air ventilator is continuously sleeved across the cavity.and again:

Remember that it is not acceptable to use mineral wool quilt or cavity brush to seal the cavity. Combustion air ventilators must be continuously sleeved - as shown on page 4

Checking Our install

Locating the vent was easy:

| Phew all looks good a 225mm x 125 airvent. Well done installer |

| Oh dear . Fly screen hasn't been removed |

The fly screen is to stop insects getting in but is explicitly prohibited by building regs when it is used as a vent for combustion. It greatly reduces the free area of the vent to a point where it no longer provides sufficient ventilation to meets the requirements.

Lets look inside...

| The cavity is full of rubble and wool, there is no sleeve and a terracotta present airbrick in the external wall. |

“Terracotta” air bricks only provide limited free air flow and will not normally Provide sufficient combustion air."

| I cant really explain this but theres a piece of wood wedged firmly bridging the cavities and some fag packet wrappers. |

Again from the CIGA guide.

If there is not enough air, poisonous gases such as carbon monoxide may be produced. These could build up and cause serious illness to the occupants. In severe cases, it could kill them.

CIGA inspection

I specifically asked the CIGA inspector to look into this. He had a good look and even rummaged around the rubble.

There was no mention of it in the report. The 'Combustion vents' tick box was not even checked. And he failed to notify us not to us the appliance due to the safety concerns contain in CIGA's own guide.

I'll chalk that down to a double fail of the installer and 'overseeing' organisation.

There was no mention of it in the report. The 'Combustion vents' tick box was not even checked. And he failed to notify us not to us the appliance due to the safety concerns contain in CIGA's own guide.

I'll chalk that down to a double fail of the installer and 'overseeing' organisation.

Comments

Post a Comment